Modular Wiring Systems: A Complete Guide

- Dec 19, 2025

- 3 min read

Electrical systems are evolving to meet demands for faster, safer installations, and one of the most prominent innovations leading this change is modular wiring.

What is modular wiring? It’s a pre-engineered wiring approach designed to improve installation speed, safety and flexibility. Unlike traditional wiring methods that require cutting, stripping and manual terminations on-site, modular wiring systems use preassembled cables and connectors that simply plug together. The smart design reduces labor time and minimizes installation errors while supporting greater consistency across all projects.

In traditional wiring, electricians spend hours routing conductors and terminating connections, which can introduce variability and safety risks. On the flip side, modular wiring offers a streamlined process that integrates seamlessly with modern electrical installation needs. The result? Higher productivity, lower costs and improved energy management efficiency across commercial and industrial environments.

Key Components of Modular Wiring Systems

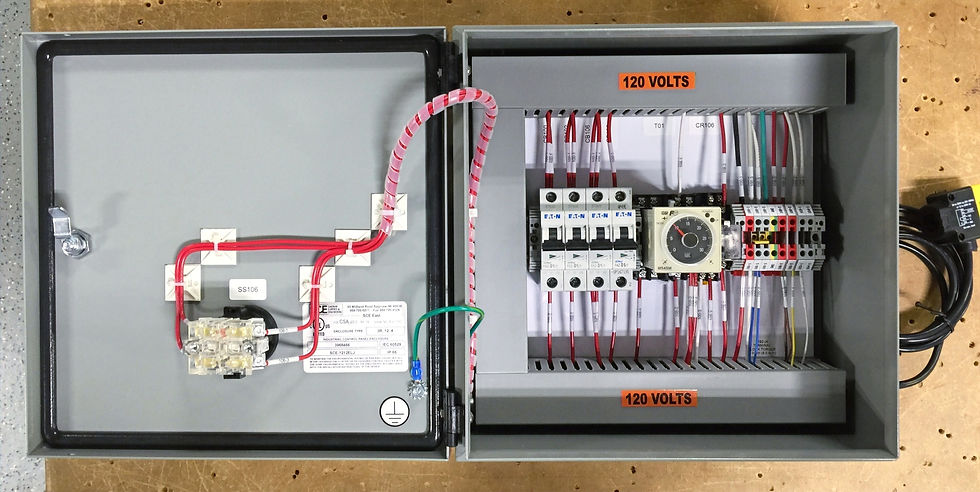

At the heart of modular wiring are standardized components designed for efficiency and safety. Modular wiring components typically include pre-terminated cables, plug-and-play connectors and distribution boxes that centralize power delivery. Each element in a modular wiring system is factory tested to meet modular wiring standards, reducing the need for on-site inspections.

Safety is central to every design. Built-in locking mechanisms and coded plugs help prevent mismatched connections, supporting adherence to modular wiring safety protocols and national electrical standards. Systems that follow the latest modular wiring technology guidelines also tend to deliver superior energy efficiency and reduced downtime during retrofits.

Benefits of Modular Wiring Over Traditional Methods

The benefits of modular wiring go beyond the time savings. Prefabrication provides predictable performance and improved project coordination, with contractors reporting reduced rework costs and faster commissioning timelines.

When comparing modular wiring vs traditional wiring, the difference in flexibility and scalability is significant. Modular wiring allows quick reconfiguration of lighting zones or power circuits with minimal disruption, making it ideal for facilities that evolve over time. Modular wiring efficiency also reduces power loss across systems. Looking at modular wiring cost analysis, strong returns are seen through lower labor expenses and minimized material waste.

Modular Wiring Design and Installation Guide

Effective modular wiring design starts with careful planning of circuits and load requirements. Systems are often configured in modules, making future upgrades simple. Designers use digital modeling tools to map out components and connections in advance to streamline field installation.

When it’s time to install, follow the modular wiring installation guide by connecting each preassembled cable according to manufacturer instructions. Always verify that the connectors meet standards for polarity, load ratings and labeling; installers should observe modular wiring safety protocols throughout the entire process. Pairing modular systems with Prefab Electrical Conduit Solutions further strengthens protection, efficiency and code compliance.

Troubleshooting and Maintenance of Modular Wiring Systems

Like any electrical solution, modular systems require periodic inspection. Following a modular wiring troubleshooting plan makes it easy to identify issues such as loose connectors or load imbalance early, allowing technicians to isolate and repair faults quickly.

Preventive maintenance is what makes longevity possible. Stick to modular wiring maintenance tips like checking for wear, contamination or signs of overheating, as well as routine cleaning and connector inspection to support consistent performance and minimize downtime.

Modular Wiring Compliance Checklist and Safety Protocols

The right modular wiring compliance checklist simplifies adherence to local codes, manufacturer recommendations and safety standards. The most important considerations: the use of UL-listed components, verified mechanical connections and circuits labeled accuracy.

Organizations that follow protocols reduce the risk of short circuits and other hazards. Meeting modular wiring standards helps safeguard system integrity, while proper modular wiring design and modular wiring installation techniques further support compliance and user safety.

Latest Trends and Innovations in Modular Wiring

The modular wiring market is steadily gaining momentum as industries shift toward smart and sustainable building solutions. Market trends show rising adoption in healthcare, data centers, and modular construction, while innovations like IoT-enabled components for remote monitoring and diagnostics continue to emerge.

Applications of modular wiring are expanding to residential sectors as builders realize that pre-engineered systems reduce project delays. As a result, modular wiring efficiency continues to improve with systems becoming more compact, intelligent and easier to integrate with building management platforms.

Modular Wiring Key Takeaways

Redefining how buildings are wired, modular wiring is offering safer, faster and more adaptable solutions. From installation through long-term operation, these systems bring measurable benefits in performance and cost savings. And with continued innovations in the sector, modular wiring systems are set to shape the future of efficient electrical infrastructure.

Comments