Types of Electrical Fittings: A Complete Guide to Safety and Applications

- SQUADPLAN @SQAUDPLAN

- Dec 19

- 7 min read

Electrical fittings are essential components that keep modern power systems safe, reliable and efficient. From basic electrical connectors to advanced smart electrical fittings, these parts make sure current flows securely from one point to another while reducing the risk of hazards. Whether you’re a homeowner, electrician or facility manager, knowing the types of electrical fittings and how they work helps support compliance, safety and long-term performance.

In homes, fittings like outlets and switches bring power to appliances and lighting systems. For industrial settings, more robust components like conduits and heavy-duty connectors protect electrical wiring from heat, corrosion and vibration. Proper installation and product selection directly influence how efficiently energy moves through a building.

Electrical fittings also reduce electrical losses, improving performance and energy efficiency. When high-quality materials and compliant fittings are used, systems experience fewer failures and lower maintenance costs. Ultimately, choosing the right fittings means protecting people, property and power reliability all at once.

Common examples include switch types, outlet types and electrical connectors. Understanding their purposes helps anyone working on electrical projects — large or small — make safer, more informed decisions.

Common Electrical Fittings and Their Applications

Every electrical system, from a simple lighting setup to a complex industrial grid, relies on several key fittings that perform distinct functions:

1. Electrical Junction Boxes

Electrical junction boxes protect and organize wire splices. They serve as central points for electrical connections and are required by most codes to reduce the risk of electrical fires. Residential electricians use them inside walls or ceilings to manage multiple circuits, while industrial facilities often use sealed or metallic junction boxes to handle higher voltages and environmental stress.

Junction boxes also simplify troubleshooting. When circuits fail, accessible junctions allow quick repairs without tearing into walls or conduit lines, saving time and labor.

2. Switches and Outlets

Switches are one of the most visible types of fittings. Each switch type — single-pole, three-way, dimmer or smart — serves a unique function. A single-pole switch controls one light, and three-way switches allow multiple control points for hallways or large spaces.

Outlet types vary in voltage and protection. For example, GFCI outlets prevent shocks near water, AFCI outlets stop electrical arcs in bedrooms or offices and USB outlets power modern electronics without adapters. Selecting the right outlet helps with proper load handling and adherence to the National Electrical Code (NEC).

3. Electrical Connectors

Electrical connectors couple wires or cables to maintain a stable circuit. They come in many designs, including crimped, soldered and compression connectors.

Using the wrong connector can create resistance that leads to overheating, but the right one can boost efficiency and lifespan. In industrial systems, heavy-duty connectors with locking mechanisms withstand vibration and moisture exposure.

4. Conduits and Cable Management

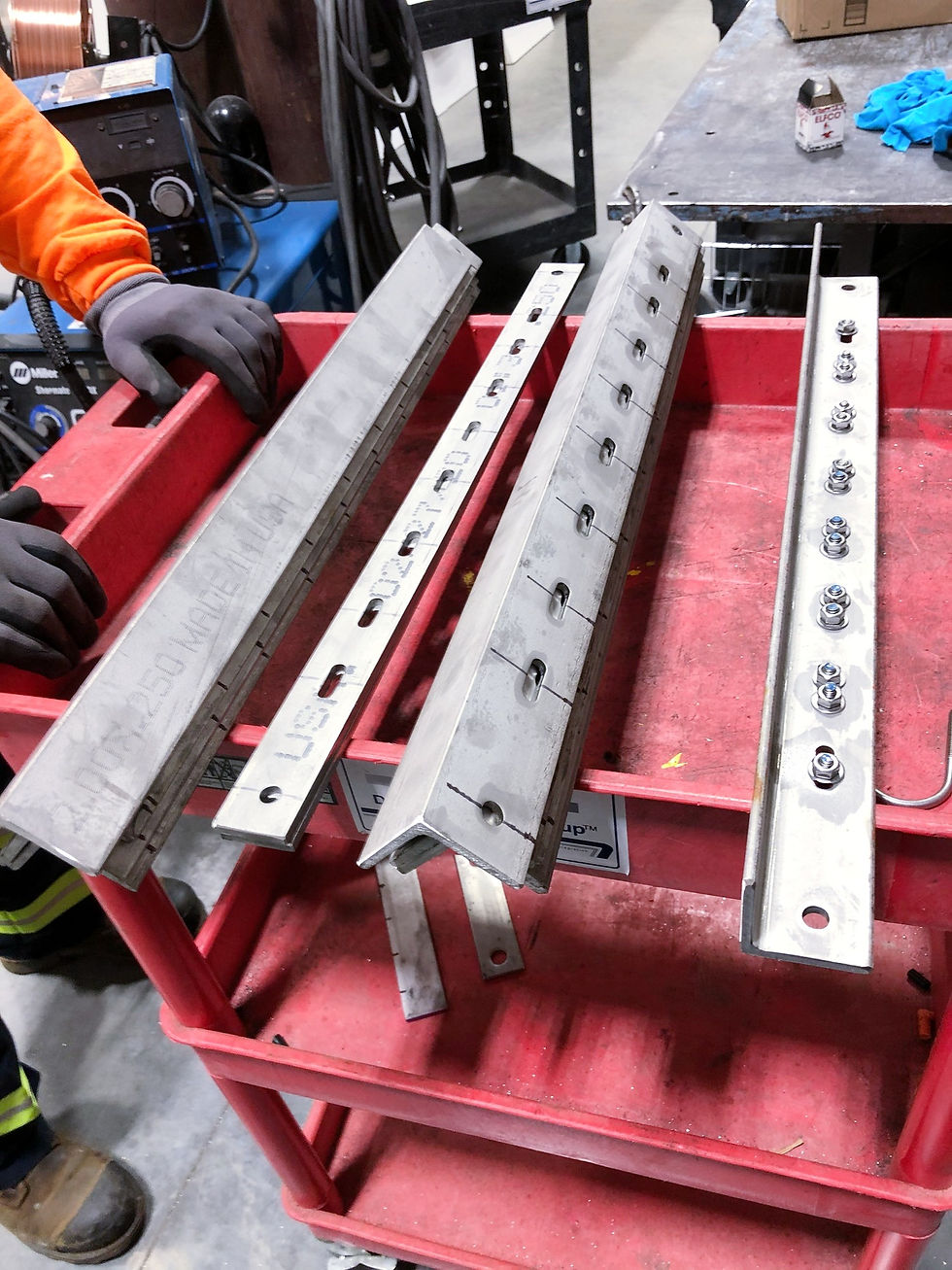

Proper cable management prevents clutter, overheating and premature wire damage. Electrical conduit systems protect and organize wiring along walls, ceilings and underground paths.

PVC conduit is lightweight, non-corrosive and cost-effective, making it ideal for residential installations. Metal conduit — including rigid, intermediate and flexible types — provides superior shielding and mechanical protection in commercial and manufacturing environments. Conduit fittings like elbows and couplings make these systems adaptable for different layouts.

Working together, conduits and fittings form structured pathways that keep wiring safe, accessible and compliant with safety standards.

Innovations in Electrical Fittings

As electrical systems continue to evolve, new technology is meeting the moment, transforming how power is distributed and managed.

Smart Electrical Fittings

Smart electrical fittings integrate automation and wireless technology into outlets, switches and connectors. These devices can be controlled remotely through mobile apps or building management systems. For example, smart switches can automatically turn off lights during unoccupied hours, saving energy in both homes and industrial facilities. They also provide valuable data on energy usage that helps identify inefficiencies over time.

Smart fittings also support safety; many detect overloads or overheating and automatically shut off power. In large buildings, this proactive monitoring helps facility managers prevent electrical fires before they start.

Innovative Wiring Solutions

Modern innovative wiring solutions streamline installations, reduce wiring errors and support flexible layouts. Preassembled harness systems, modular raceways and quick-connect fittings all simplify upgrades and maintenance, making them especially helpful in industries like healthcare and manufacturing where downtime is costly.

Flexible metal conduits are another prime example of innovation, allowing safe movement in machinery that vibrates or shifts during operation. Flexibility prevents wire fatigue, which can otherwise cause dangerous shorts or open circuits.

Energy-Efficient Connectors

Energy-efficient connectors minimize resistance between wires and terminals so that more power reaches its destination. In large-scale operations, this can mean significant energy savings. Advanced designs with spring-loaded or silver-plated contacts maintain firm connections that don’t degrade over time.

The embrace of energy-efficient fittings falls in line with broader sustainability goals, helping companies meet energy-reduction targets and lower operational costs at the same time.

Understanding Circuit Breakers and Fuses

Both circuit breakers and fuses protect electrical systems from overload, but they do so in slightly different ways.

Circuit Breakers

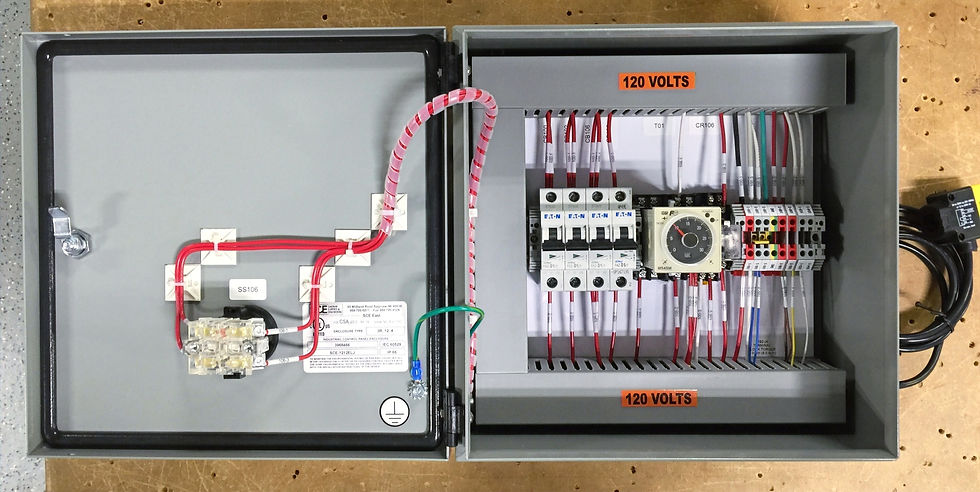

Circuit breakers act as automatic switches that interrupt power when current exceeds a safe level. They can be reset manually or electronically after tripping for convenience and reusability. Industrial facilities often use advanced circuit breakers that can be monitored remotely for real-time performance data.

Breakers stop costly damage to sensitive equipment and confirm that circuits operate within safe limits. Many modern models are designed for integration into smart panels that communicate with building management systems.

Fuses

Fuse types still play a role in many electrical installations because they provide quick, reliable protection at low cost. A fuse contains a thin metal filament that melts under excessive current, breaking the circuit instantly. Rapid response is particularly valuable for delicate electronics, where even just milliseconds can make a massive difference.

While fuses must be replaced after blowing, they remain popular for specific control circuits, lighting panels and older infrastructure due to their simplicity.

Comparing the Two

Circuit breakers offer a blend of convenience and flexibility, while fuses deliver speed and precision. In many modern systems, the two are used in tandem: fuses for device-level protection and breakers for system-level control.

Electrical Safety and Maintenance

No electrical system can remain safe without regular upkeep. Preventive measures protect both people and property while extending equipment lifespan.

Preventive Electrical Maintenance

Preventive electrical maintenance involves inspecting and testing equipment before failure occurs. Infrared scanning, torque checks on terminals and insulation resistance testing all help identify hidden problems.

Regular maintenance schedules are critical for commercial buildings, where unexpected downtime can bring operations to a halt. A well-documented maintenance plan also supports regulatory compliance, showing that systems are inspected and serviced according to OSHA and NEC standards.

Home Electrical Safety Tips

For homeowners, following some simple safety tips can avoid many preventable accidents:

Replace frayed cords and damaged plugs immediately

Avoid daisy-chaining multiple power strips

Never use water near electrical devices

Keep extension cords temporary, not permanent

Together, these habits help reduce the risk of shock and fire in residential settings.

Grounding Techniques and Cable Management

Proper grounding techniques are paramount for safely diverting excess current into the earth. Done correctly, grounding eliminates the risk of shocks, protects appliances from surges and stabilizes voltage.

Meanwhile, structured cable management makes sure that wires are separated by function and properly secured, reducing interference and overheating. Industrial environments use industrial grounding techniques — such as ground bars and rods — to stabilize high-voltage systems under load.

Choosing the Right Electrical Fittings for Your Project

More than just combability, selecting electrical fittings means designing for safety, efficiency and longevity.

Start by identifying the application; residential projects need fittings rated for 120–240 volts, while industrial systems often require higher current capacities. Outdoor or corrosive environments call for weatherproof and rust-resistant materials.

Next, verify compliance with electrical safety regulations. Components tested to UL or IEC standards guarantee consistent performance. In commercial installations, inspectors will look for markings that confirm proper certification.

Energy efficiency also matters. Using energy-efficient connectors and smart electrical fittings reduces waste and lowers energy bills. Facility managers can even integrate these into energy management systems to track and optimize power use.

Finally, consult with system design experts. DuFab offers industry-grade products and customized solutions that meet specific project needs and code requirements. Whether you’re outfitting a home or managing a large facility, choosing the correct fittings and working with professionals provides lasting peace of mind.

Regulations and Standards for Electrical Installations

Adhering to electrical safety regulations is non-negotiable. In the U.S., installations must follow several regulations governing design, installation and maintenance.

The National Electrical Code (NEC) outlines how wiring and fittings should be installed to prevent fires and electrocution. OSHA enforces these safety rules for workplaces, ensuring equipment is properly grounded and inspected. Underwriters Laboratories (UL) and IEC certifications confirm that components meet recognized safety criteria before they reach the market.

Compliance also helps prevent costly fines, delays in construction or renovation projects. Inspectors must confirm installations meet code before issuing occupancy certificates or approvals. Working with a trusted supplier like DuFab simplifies the process from start to finish, so you can rest easy knowing that all fittings meet the latest compliance requirements.

Bringing It All Together: Electrical Fittings for Safety and Performance

Selecting the proper types of electrical fittings plays a major part in both safety and efficiency. From simple electrical connectors to intelligent smart electrical fittings, each part contributes to safer power distribution and long-term performance.

As technology evolves, innovations like energy-efficient connectors and innovative wiring solutions will make it easier to design sustainable systems that meet modern energy standards. Regular preventive electrical maintenance and adherence to electrical safety regulations helps those systems remain reliable for years to come.

Comments